Select Your Vehicle

1964 Chevy Corvette Truck Brake Pads

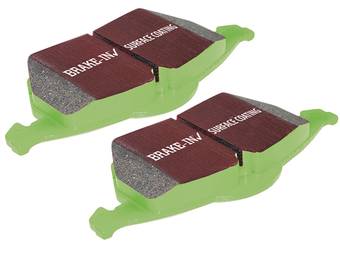

Truck Brake Pads

Whether you’re hauling a heavy load up and down steep grades or ripping around an autocross track, having high-quality brake pads is essential. Brake pads are a vital component of your vehicle’s braking system. As you depress the brake pedal, hydraulic pressure flows through brake lines into the calipers to extend the caliper's pistons, forcing the abrasive brake pads into your vehicle’s rotors. The resulting friction slows and eventually stops your truck, Jeep, or SUV!

After tens of thousands of miles and countless stops, friction eventually wears the brake pad material, requiring a replacement to restore full braking performance. Symptoms of excessively work brake pads include:

A high-pitched squealing sound when depressing the brakes, typically caused by the brake wear indicator of the pad rubbing against the rotor’s surface; replace soon

An aggressive, grinding sensation that’s both audible and felt in the brake pedal; stop driving and replace immediately

Pulling to one side while depressing the brakes

Poor braking performance

Aside from replacing brake pads as regular maintenance, you can also upgrade to a high-end brake pad to improve drivability, depending on your driving style. Specialty brake pads come in several compounds, offering such benefits as reduced noise, reduced dust, and improved braking performance for track use, towing, and more!

We also offer several comprehensive brake kits, including all-new brake rotors, calipers, brake pads, and hardware!

Semi-Metallic vs. Ceramic Brake Pads

Brake pads aren't one-size-fits-all; they come in several materials and compounds, offering different braking characteristics, pros, and cons. Two of the most common constructions include semi-metallic and ceramic.

Semi-Metallic

Semi-metallic brake pads are commonly found on OE applications. These pads get their name from their semi-metallic construction, including between 30 and 70 percent copper, iron, steel, and other alloys. These metals are blended with graphite lubricant and other fillers, resulting in the tried and tested semi-metallic brake pad!

Semi-metallic brake pads are often used in racing and heavy towing applications, considering the harder bite of their metallic construction. They also resist fading as heat is applied, making them ideal for high-stress applications. This being said, semi-metallic brake pads are also more abrasive. These pad compounds wear rotors faster and more aggressively than ceramic and other organic materials.

Ceramic

By comparison, ceramic brake pads offer quiet, comfortable, low-dust performance; however, they’re less abrasive, more prone to brake fade, and thus, less effective on high-stress applications.

Ceramic brake pads are ideal for daily driving and light towing, keeping your wheels clean and significantly outlasting semi-metallic pads! And considering ceramic pads are less abrasive, they prolong the life of your vehicle’s rotors and other braking components.

Brake Pad Resources

For more information on brakes and brake pads, check out our related features on RealSource!